Mexico amazes in the battle against Covid-19 with graphene as a secret weapon

The only reliable face shields accessible within the market are made from Mexican Graphene and it’s thanks to a combined exertion of private initiative and Mexico City’s government, and the leading news is that, even if graphene is known to be a costly fabric, the price of these graphene face shields are even less than a regular one.

In weeks, the Mexican company Energeia Graphenemex got to be a crucial supplier within the health care sector by providing high-tech face shields, which raises an effective barrier against coronavirus, and which are priced below the average of face shields directly in a market that has all of a sudden gotten overwhelmed by the fear of the pandemic, charging ridiculous prices for them.

Founder and CEO of Energeia Graphenemex, Antonio Miramontes spoke about the most recent result of eight years of research and development of applications for graphene. “It has been an intense period in which we have tested the vision of Mexican investors and scientists, achieving success two years ago in the sector of anticorrosive and antimicrobial coatings, thanks to the impermeability capacity that graphene has,” Miramontes said.

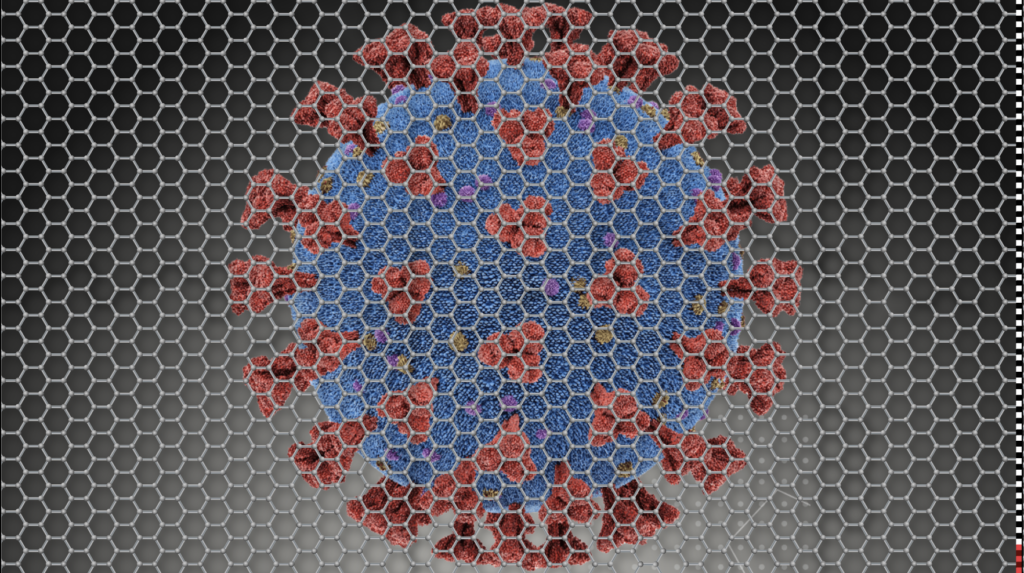

Collectively with a group of manufacturing plants in Mexico City, Energeia Graphenemex currently produces 200,000 face shields a day for the doctors and staff of the The Mexican Institute of Social Security (IMSS), The National Health Institute for Well-Being (Insabi) and the local government. “Our face shield has an acetate with an internal layer of recycled PET and two external layers of graphene, a material that results from processing the graphite and bringing it to an atom of thickness in the lab and which its properties and applications are still being investigated in various countries, he emphasizes.

The graphene oxide face shields have a porosity of less than five nanometers (one billionth of a meter). If you consider that the size of the coronavirus diameter, SARS-CoV-2 is between 80 and 120 nanometers, it would be as if trying to fit a tennis ball into a mosquito net. This project received the support of the Ministry of Education, Science, Technology and Innovation (SECTEI) of Mexico City since March, as well as the UNAM and the IPN. “It is an example of effective coordination between public institutions, Energeia Graphenemex and several manufacturing companies,” Miramontes points out.

“Once we had the prototype of the mask at the end of March, in April we started with the production of 30 thousand masks a day, which are already 200 thousand. What we are working on now is in a redesign to make the masks more anatomical, in other words, adaptable to the human face and we are also working on making garments such as caps, gowns and suits for the medical staff made of fabric with graphene oxide, and soon we will also be manufacturing face masks ”.

“Public safety staff and their well-being has been the number one priority for this joint effort, from health institutes to security, cleaning and sanitation employees, but the demand has begun to come from private companies that need to provide protection accessories to their staff on the return to work activities”, Miramontes stresses.